The Importance of Integration Testing for BMS Systems: A Case Study on NXP 6cell and 14cell systems

As a BMS (Battery Management System) producer, we understand the importance of providing high-quality BMS systems that meet the highest standards. Our commitment to quality and reliability is evident in our Testing and Production process (TPS) for NXP’s individual 6-cell or 14-cell BMS systems.

Our BMS systems are designed to provide efficient and reliable management of both new and recovered batteries. We are committed to reducing waste and contributing to a more sustainable future. Our BMS systems are capable of managing batteries that have been recycled, recovered from crashed EV batteries, and even those that are brand new. Our subsystems’ primary function is to ensure that these cells can be safely and effectively reused, thereby reducing waste and contributing to a cleaner environment.

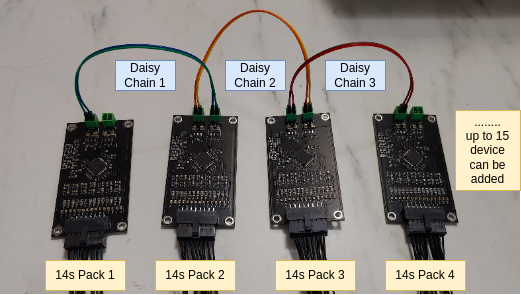

The Integration test is a crucial part of our Testing and Production process (TPS) for NXP’s individual 6-cell or 14-cell BMS systems. During this testing process, our team of experts rigorously tests the BMS system’s components and functions to ensure that they meet the specifications and requirements of the project. We ensure that the BMS system’s communication protocols are verified, the system’s performance is monitored, and the accuracy of the measurements and data collected is verified.

We understand that BMS systems are crucial in the development of sustainable energy solutions. Therefore, we take great pride in the quality of our BMS systems and their important role in contributing to a cleaner environment. By providing reliable and efficient battery management, we help our customers reduce waste, lower costs, and contribute to a cleaner environment.

Our BMS systems are designed to withstand harsh environmental conditions and can operate in extreme temperatures. We use high-quality components and follow strict quality control measures to ensure the reliability and durability of our BMS systems.

We have a team of experienced engineers who are knowledgeable about BMS systems and are dedicated to providing the best customer service. We are committed to providing timely support to our customers and ensuring that our BMS systems meet their requirements.

In conclusion, we are committed to providing high-quality BMS systems that meet the highest standards. Our BMS systems are designed to provide efficient and reliable management of both new and recovered batteries, contributing to a more sustainable future. Our rigorous testing process ensures that our BMS systems meet the specifications and requirements of the project, providing our customers with reliable and efficient battery management.

Leave a Reply

Please prove you are human to comment on this post. It will take less than a minute.